Hooke’s

Law – Computer Applications Assignment 1

Hooke’s Law is the law of elasticity discovered by Robert Hooke in 1660, which

states that, for relatively small deformations of an object, the displacement

or size of the deformation is directly proportional to the deforming force or load.

(1)

Deformation of a solid is caused by a force that can either

be compressive or tensile when applied in one direction. Compressive forces try to compress and object

while tensile ones try to tear it apart. We can study these effects by looking

at what happens when you compress or extend a spring. (2)

The equation which relates deformation to load is written

as;

F=-kx (Equation 1(3))

In equation 1, F is equal to the force applied; k is the

spring constant of the material and x is the amount of displacement observed.

When plotting a graph of load against displacement, a linear

relationship is observed.

(Figure 1 (2))

(Figure 2 (2))

(Figure 3 (2))

Figure 2 shows the relationship between force and extension

for a strong, brittle material. There is very little extension for a large

force, but the material suddenly breaks and fractures. It is defined as being

brittle because the material fractures instead of bending. An example of a brittle material is glass. (2)

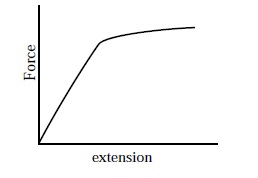

Figure 3 shows the relationship between force and extension

for a plastic material. The material undergoes a large deformation with only a

little force applied. The linear relationship of Hooke’s Law only lasts for a

short time. It is defined as being plastic because it is more likely to bend

than to fracture. (2)

(Figure 4 (2))

Figure 4 shows the relationship between force and extension

for a ductile material. The material shows the behaviour of a plastic material,

after Hooke’s Law has been exceeded, over a range of forces before

fracturing. Ductility is the ability of

a material to be stretched into a new shape without breaking. An example of a ductile material is aluminium. (2)

Most Hooke’s Law experiments are carried out by hanging

weights onto a spring and recording how much they extend by. Here is a video demonstrating how to set up and conduct a Hooke's Law experiment.

Figure 5 shows how when the force acting on the spring doubles, the spring's extension also doubles.

(Figure 5 (5))

Here are a few videos

which explain Hooke’s Law and what to expect from a force and displacement

graph.

The following results were obtained from a Hooke’s Law

experiment.

x

|

y1

(Material 1)

|

y2

(Material 2)

|

z

(Material 3)

|

1

|

3

|

2.2583

|

2.375

|

2

|

4.5

|

4.3166

|

9.375

|

3

|

6

|

6.3749

|

28.375

|

4

|

7.5

|

8.4332

|

65.375

|

5

|

9

|

10.4915

|

126.375

|

6

|

10.5

|

12.5498

|

217.375

|

7

|

13

|

14.6081

|

344.375

|

8

|

14

|

16.6664

|

513.375

|

9

|

15

|

18.7247

|

730.375

|

(Table 1)

In table 1, x is the amount of force applied in Newtons, and

the values shown in the material columns show the amount of deformation in the

material in mm. When plotting materials

1 and 2 on a graph, a trend becomes evident.

(Figure 6)

Figure 6 shows, that both materials have a linear

relationship with force and extension. This means that Hooke’s law is being

obeyed throughout all points of the experiment. This also implies that, once

the load is removed, the material will return to its original shape. Also, as

the relationship is linear, they both follow equation 4 which is the equation

of a straight line.

Y=mx+c (Equation 4)

Using equation 4, it is possible to work out the gradient of

the slope and also the y intercept. In equation 4, the gradient of the slope is

equal to m and the y intercept is equal to c. In this case, the gradient is a

constant and is also equal to the spring constant of the material itself. Equation

2 shows the spring constant for material 1 as being 1.5583 Nm-1.

Equation 3 shows that the spring constant for material 2 as being 2.0583 Nm-1.

The y intercept shows the force applied when displacement is

zero. It is to be expected that the y intercept for Hooke’s law will be equal

to zero. That is to say, that when there is zero force applied, zero

deformation is observed. However, as can be seen from equations 2 and 3, there

is a value of 0.2 and 1.375 respectively. These values obtained for the y

intercept is due to choosing a line of best fit from the data collected.

It is also possible to use the graph in figure 6 to show the

point where the force-extension relationships for both materials intersect each

other. It is at this point where both materials will extend by the same amount

when the same force is applied to them. According to the graph this occurs at

roughly 2.3N. This can also be attained by using the laws of simultaneous

equations to equations 2 and 3 in the following way.

First arrange the equations together as equation 2 is equal

to equation 3 to get equation 5;

2.0583x + 0.2 =

1.5583x + 1.375 (Equation 5)

Next, make x the subject of equation 5 to get equation 6;

2.0583x – 1.5583x

= 1.375 – 0.2 (Equation 6)

Next, do the subtraction on both sides of the equation to get

equation 7;

0.5x = 1.175 (Equation

7)

Finally divide both sides of equation 7 by 0.5 to leave

equation 8;

X = 2.35 N (Equation

8)

The value which appears on figure 6 is very close to the

value obtained in equation 8. It is not identical due to the graph in figure 6

not being presented in enough detail to gain an exact reading of where the

intersection takes place.

(Figure 7)

References

1.

Unknown. (2012). Hooke's Law. Available:

http://www.britannica.com/EBchecked/topic/271336/Hookes-law. Last accessed 12th

Nov 2012.

2.

Unknown. (6th Oct 2009). What Is Hooke's Law?. Available:

http://engineers4world.blogspot.co.uk/2009/11/hookes-law.html. Last accessed

12th Nov 2012.

3.

Unknown. (2012). Determine The Spring Constant. Available:

http://www.4physics.com/phy_demo/HookesLaw/HookesLawLab.html. Last accessed

12th Nov 2012.

4.

QuantumBoffin. (7th Nov 2009). Stretching a Spring. Available:

https://www.youtube.com/watch?v=OHyfoM2vIUs&feature=related. Last accessed

13th Nov 2012.

5.

Nave, R. (Unknown). Elasticity

- Hooke's Law. Available:

http://hyperphysics.phy-astr.gsu.edu/hbase/permot2.html. Last accessed 13th Nov

2012.

6.

Fullerton, D. (29th Nov 2011). Springs

and Hookes Law. Available:

http://www.youtube.com/watch?v=6MhaPzGxfV8&feature=related. Last

accessed 13th Nov 2012.